MKK Metal Sections Pvt Ltd, founded in 2008 by the late industry pioneer Late Shri.Mahesh Khandelwal, stands as a testament to unwavering dedication and industry innovation. We're more than a company - we're a community of over 500 committed professionals, relentlessly pursuing excellence in every facet of our operations.

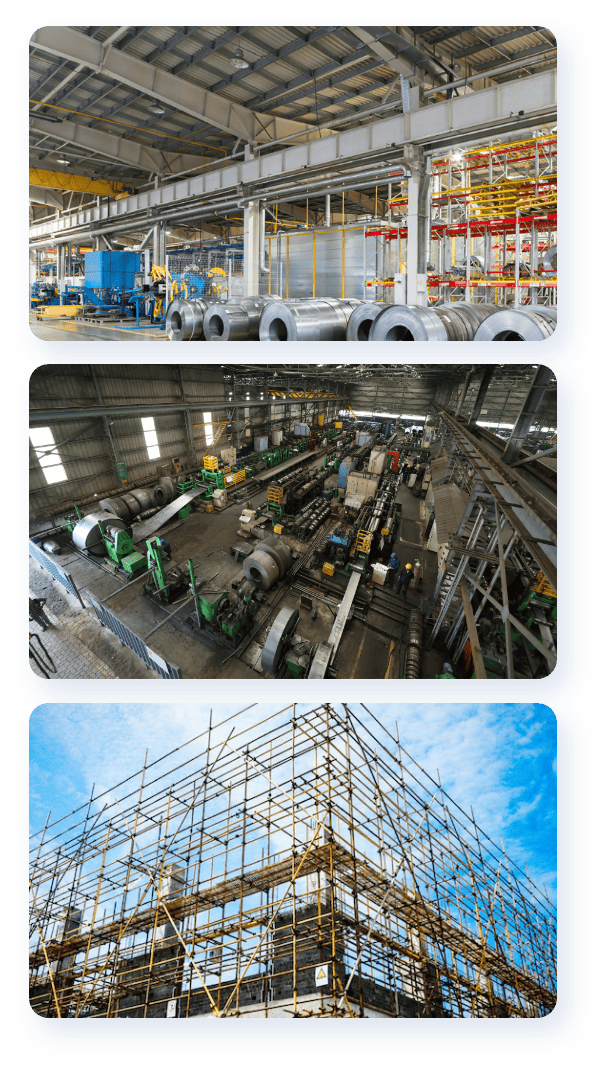

Our growth at MKK has always been gauged by the value we add to our customers' endeavours, a strategy that has rooted us in the core ethos of customer-centric service. Our fully integrated manufacturing facility, an ISO 9001:2015 certified entity, employs top-tier industrial practices to produce high-quality, enduring products that meet a wide spectrum of commercial and industrial needs.

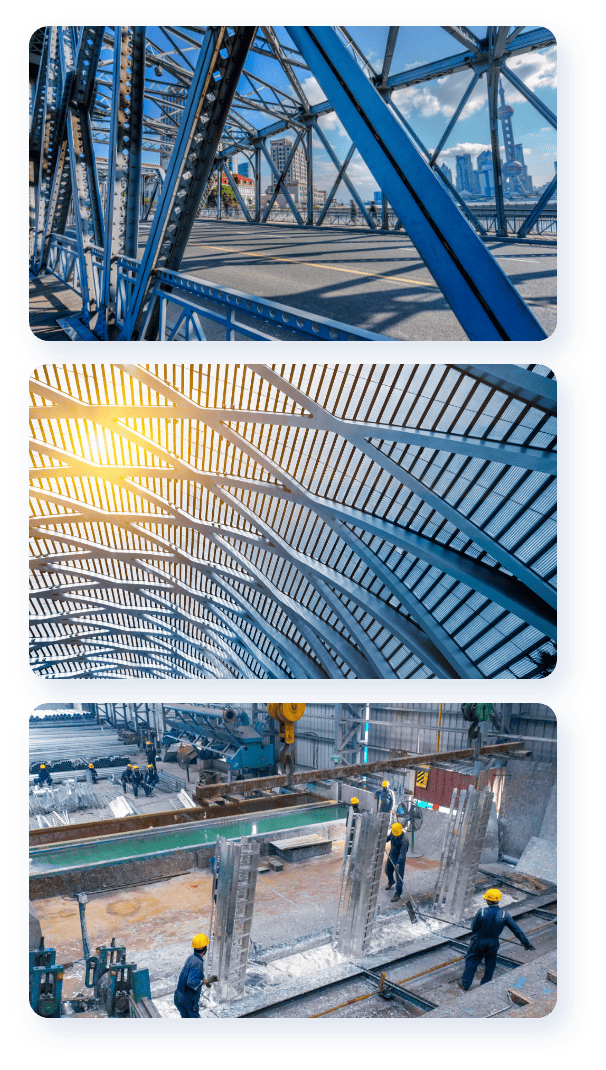

Silently powering the nation's most ambitious infrastructure projects, MKK's touch can be felt everywhere - from bustling airports and railway stations to thriving malls and metros, expansive solar plants, and sprawling industrial and residential complexes.

We don't just offer products; we provide solutions. With our competitive pricing and active presence in the industry, we're geared to meet your every need. Reach out today, and let's create your industry solution together.