Established in 2008 by the visionary Late Shri. Mahesh Khandelwal, MKK Metal Sections Pvt Ltd, embodies a legacy of relentless dedication and innovation in the metal industry. As a community of over 500 skilled professionals, we are committed to excellence in every aspect of our operations.

At MKK, we pride ourselves on being the leading steel product manufacturer in Tamil Nadu. Our commitment to quality starts with selecting the finest raw materials and extends through our use of state-of-the-art technology in production. Our fully integrated manufacturing facility is ISO 9001:2015 certified, reflecting our adherence to superior industrial practices. This allows us to deliver durable, high-quality products tailored to meet a diverse range of industrial and commercial requirements. Our guiding principle is to ensure quality at every stage of production.

Our supply network spans across the region, including Karnataka, Andhra Pradesh, Tamil Nadu, and Kerala, with key cities like Chennai, Hyderabad, and Bangalore. We offer a broad array of products designed to meet specific client needs. Since our inception, we have consistently provided products that adhere to the highest industrial standards and norms.

At MKK Metal Sections Pvt Ltd, we do more than just supply products—we deliver solutions. Contact us today to collaborate on crafting the perfect solution for your industry needs.

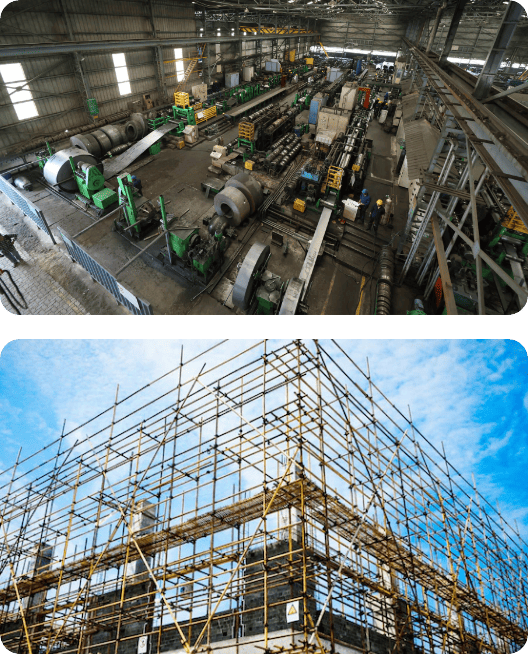

At MKK Metals, our infrastructure is at the forefront of the industry, equipped with the latest technology and ultra-modern machinery. Our infrastructural base supports an impressive annual production capacity of 2.5 lakh metric tons. Our extensive product range includes over a thousand varieties. This breadth of production makes MKK Metals the largest steel product manufacturer in Tamil Nadu.

Continuing our commitment to growth and innovation, MKK Metals has recently inaugurated a new, state-of-the-art integrated plant specialising in Hot Dip Galvanizing pipes and structures. This facility is capable of galvanising structures up to 12 meters in length and will boost our capacity by an additional 60,000 tons per annum. Our ongoing goal is to enhance customer satisfaction by centralising our services and ensuring quality and efficiency are maintained at the highest standards.