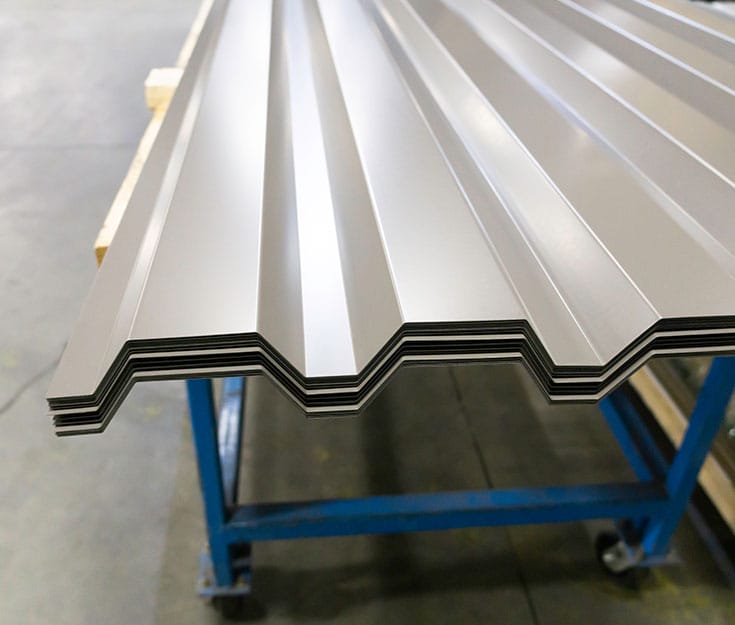

At MKK Metals, we specialise in the production of galvanised iron (GI) sheets - steel sheets fortified with a zinc coating. As a leading steel manufacturer, our selection encompasses a broad range of both hot-dipped galvanised and electro-galvanised steel sheets designed to offer superior protection for the base steel by reacting with the environment.

Our Galvanised Iron (GI) Sheets stand out for their robust resistance to rust, courtesy of their iron coating. This zinc layer safeguards the innate strength of the GI sheets, ensuring their longevity and durability. They find varied applications in the agricultural sector, serving as a reliable material for sprayers, pans, grain silos, and more.

To guarantee the optimum performance of our GI sheets, we implement rigorous quality control measures. The parameters of the chromating process are closely monitored, and our sheets undergo regular salt-spray tests. This meticulous approach ensures that our GI sheets not only meet but exceed industry standards, delivering unrivalled quality to our clients.

Our Galvanised Iron (GI) sheets, prized for their versatility and rust-resistant attributes, cater to a multitude of applications across various industries and sectors:

An ideal choice for roofing sheets, fencing, wall panels, gutters, balcony panels, roof grills, window frames, rolling doors, warehouses, pipes, and door panels.

A preferred material for the outer shells of tractors and cars, bicycle frames, bottom plates, inner panels, containers, ship bulkheads, agricultural machinery, and highway fences.

Utilized in the construction of back panels and shells of a wide array of household appliances, including washing machines, air conditioners, refrigerators, water heaters, microwave ovens, kitchen utensils, and chimneys.

Frequently employed in crafting tables, wardrobes, bedside cabinets, bookshelves, file cabinets, and more.

From outdoor billboards, nuts, hoppers, nails, and bolts, to solar projects, fermentation tanks, and buckets, the use cases for our GI sheets are nearly endless.

Hot-dipped galvanised GI sheets are subjected to immersion in molten zinc, resulting in a substantially thicker and more robust coating, making it apt for outdoor utilisation. On the other hand, electro-galvanised GI sheets acquire their zinc coating via an electroplating process, producing a thinner coat often used in indoor or decorative settings.

Absolutely. GI sheets are highly adaptable to cutting and fabrication processes. They can be readily cut, shaped, and formed to cater to specific project needs. This flexibility positions them as an apt choice for a range of applications across the construction, automotive, and manufacturing sectors.