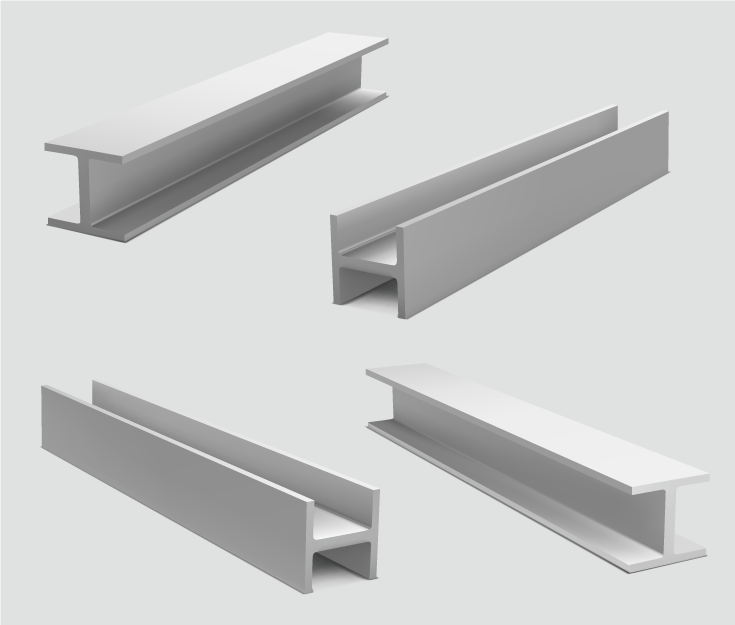

The Top Hat Section, a product of MKK Metal Sections Pvt Ltd, a leading steel pipes manufacturer, stands out as a premium structural element crafted from high-quality mild steel. Its unique top hat shape not only lends it a distinctive appearance but also ensures superior strength and durability. This meticulously engineered profile is designed to deliver an exceptional balance of lightness and structural rigidity, making it an optimal choice for a wide range of applications in India's automotive, construction, and industrial sectors.

Thanks to its refined design, our Top Hat sections combine functionality with aesthetics, featuring a polished finish that not only enhances its visual appeal but also improves corrosion resistance. This ensures its lasting performance in various environmental conditions, solidifying its position as a versatile and reliable solution for industry professionals.

Each Top Hat Section is crafted with meticulous attention to detail, ensuring unbeatable precision in dimensions for flawless integration across diverse applications.

Our Top Hat Sections boast unparalleled structural efficiency, facilitating the creation of structures that are both lighter and incredibly sturdy.

Perfectly suited for an array of uses, including trusses, vehicle frames, and fencing, highlighting their adaptability in various projects.

Engineered for longevity, our Top Hat Sections are resistant to both corrosion and wear, presenting a durable, maintenance-free option for structural needs.

We offer customisation to meet specific project requirements, with a variety of sizes available to ensure the perfect fit for every project.

Our sections are designed for effortless integration, streamlining the construction process with their straightforward installation.

With a focus on aesthetic appeal, our Top Hat Sections are polished to perfection, enhancing the visual quality of any design or construction project.

Top Hat sections are versatile in installation, accommodating both horizontal and vertical placements to suit diverse structural requirements. Typically, they are affixed to the base structure through screw-fixing at the outer legs, with the lining material attached to the profile's broad face. The specific fixing techniques can vary, as outlined by lining board manufacturers, to adapt to the unique demands of various construction projects.

Top Hat sections are primarily crafted from high-tensile steel, ensuring robustness and longevity. They are finished with coatings of either Z350 galvanised coating or AZ150 zinc-aluminium alloy, both adhering to the AS1397 standards. These finishes provide the sections with outstanding durability and corrosion resistance, rendering them ideal for diverse environmental conditions.

Absolutely, Top Hat sections are designed for external applications. The protective coatings, including galvanised steel or zinc-aluminium alloy, offer superior corrosion resistance. This makes them perfectly suited for diverse climates, even in coastal regions prone to salt air exposure. With correct selection and installation, these sections deliver enduring performance and durability in outdoor applications.

Top Hat sections typically require low maintenance, particularly in settings with minimal exposure to corrosive factors. It's advisable to perform routine inspections to verify the condition of the protective coatings and to promptly identify and rectify any wear or damage, ensuring the sections' longevity and performance.

Yes, Top Hat sections are recognised for their environmental benefits. Their durability and extended service life lessen the frequency of replacements, thereby reducing waste. Furthermore, since steel is recyclable, the use of Top Hat sections aligns with eco-friendly principles. Their efficiency in construction supports sustainable building methods by optimising material usage while maintaining structural strength, contributing positively to environmental sustainability.