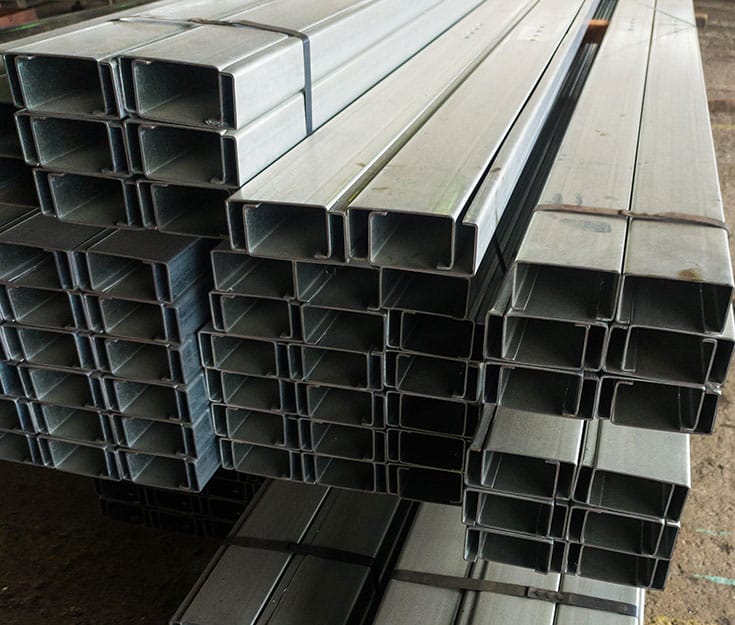

MKK Metal Sections Pvt Ltd is renowned in the industry as a leading manufacturer of structural C and Z purlins, vital for various industrial applications. These purlins, essentially steel beams, run along the length of the roofing structure, providing the robust and enduring support necessary for industrial construction.

In layman's terms, our purlins serve as the backbone of the roofing structure, lending it strength and stability. As a trusted steel pipes manufacturer in Tamil Nadu, we apply the same precision to our purlins, which are classified as ZEE, ZED, and CEE-shaped (Cold formed). Each purlin is meticulously roll-formed from pre-galvanized sheets, featuring a zinc coating mass ranging from a minimum of 120 GSM to a maximum of 275 GSM, ensuring top-notch durability and performance.

Tailor the length to your specific needs, eliminating material wastage.

Benefit from quick rejection and effortless handling.

Our purlins come pre-punched for your convenience, removing the need for onsite drilling or cutting.

With perfect dimensions, strength, and straightness, our purlins meet every custom requirement.

Lightweight in comparison to conventional MS Channels/ Angles, our purlins offer a distinct cost advantage.

The cold roll forming process ensures close tolerances on sectional sizes for absolute precision.

Expect to save 30-50% in terms of weight and steel usage and 20-30% in overall construction cost.

C and Z purlins deliver numerous benefits over conventional timber roof supports. Their lighter weight, increased durability, and resistance to rot, pests, and fire make them superior alternatives. Moreover, they offer consistent dimensions, eliminating the inconsistencies commonly seen in timber. Cost-effective and easy to install, these purlins possess excellent load-bearing capabilities, thereby making them a popular choice in contemporary construction.

Absolutely! At MKK, we understand the necessity of adhering to precise design specifications. Our range, including the C and Z purlins, can be customised to meet specific requirements, assuring optimal performance and structural soundness. Our seasoned team excels in delivering bespoke solutions to suit diverse construction needs.

Sustainability is one of our core principles at MKK. We do offer eco-friendly options for our products. Our sections can be manufactured using recycled materials, actively contributing to resource preservation. Additionally, our surface finishing processes are environmentally friendly, minimising the utilisation of harmful chemicals. Our goal is to offer products that meet your performance expectations while also aligning with your environmental commitments.

Definitely. Our products are engineered with resilience in mind, enabling them to withstand a range of weather conditions. Whether exposed to intense heat, heavy rainfall, strong winds, or corrosive environments, our sections, door frames, and rolling shutters are designed for durability and long-lasting performance. The selection of materials and application of appropriate surface finishes ensure weather resistance and preserve product integrity.